018 2725 9346

Advanced crystallisation Process (ACP)™

LCS – proud suppliers and installers of Advanced Crystallisation Process (ACP)™

As Great Britain is largely made up of limestone and chalk, around 60% of properties in England and Wales are supplied with hard water. Do you suffer with hard water in your area? Are you tired of limescale issues? Have you tried ways to solve limescale? Is limescale costing you time & money?

What is Limescale?

Hard water which contains a lot of lime (Calcite) which will lead to a build up of limescale. You will spot signs of limescale by seeing a stony off-white crust inside your kettle, or a covering on taps or shower heads. It becomes a nuisance when hard water drys as a chalky water stain on surfaces, especially glass, also if you shower and find your skin feels dry and irritated this is probably due to the hardness of your water.

The drawbacks of ‘Hard Water’

Limescale leaves unsightly deposits on surfaces, sometimes hard to remove

Reduces the working life of taps, pipes, toilets, tanks, boilers, washing machines and other water based equipment’s.

Reduces the effectiveness of soaps, shampoos and detergents.

According to British Water, even a thin 1.6mm coating of limescale on a heating element can make it 12% less effective costing the owner extra money.

How do you remove limescale?

To get rid of limescale there are only 2 options – condition the water, or soften the water.

Option 1: condition the water

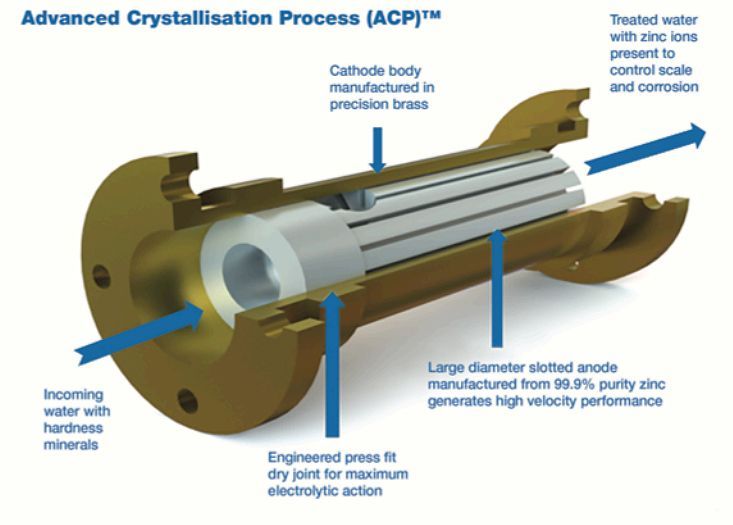

In the conditioning process, zinc in the Advanced Crystallisation Process (ACP)™ system reacts with the lime in the water to form a non-stick form of lime called Aragonite. By changing the form of lime, up to 98% of limescale formation is prevented.

Pros

- Formation of new limescale, and growth of existing deposits, is

greatly reduced.

- Any residue can simply be wiped away with a normal household cleaner.

- Lime remains in the water, so pipes and aluminum heat exchangers in condensing boilers are protected from corrosion.

- The system can easily be moved to another location or house.

- Maintenance-free.

- Up to 98% effective,and no new problems.

Cons

- Conditioning doesn’t completely remove the need for cleaning – a small amount of residue might still need wiping away.

Option 2: soften the water

In the softening process, the lime in the water is replaced by sodium. By removing the lime, limescale will no longer form.

Pros

- The hardness, i.e. the lime, is removed.

- Existing limescale is reduced.

- Less soap, detergent and shampoo is needed.

Cons

- Sodium is left in the water – about half the amount of lime it replaces.

- Fitting a separate drinking water tap is currently recommended by the UK Dept. of Health, Water Regulations Advisory Scheme (WRAS) and the UK water Trade Association (UKWTA).

- Corrosion can damage condensing boilers because of the lack of lime and the presence of sodium in the water.

- Salt has to be bought regularly, or stored if bought in bulk.

- The salted water is flushed out into the sewers, and from there into rivers and onto the land through flooding and irrigation. This increases the salinity of the soil and reduces its productivity.

- Salt has to be mined, processed and transported to its final destination.

Tell Me More About Advanced Crystallisation Process (ACP)™

Worry-free maintenance

No maintenance just change every 10 years.

Nothing to go wrong, no electrics, no moving parts.

Condensing boilers often have aluminium heat exchanger which can be corroded by the high sodium water. Call your boiler manufacture to make sure it is safe to be used with a salt based unit.

Steel radiators can be damaged by the high sodium water.

ALL boilers and ALL appliances are safe with Advanced Crystallisation Process (ACP)™ units.

Save money with Advanced Crystallisation Process (ACP)™

Advanced Crystallisation Process (ACP)™ is cheaper to buy than most high quality water softeners.

Advanced Crystallisation Process (ACP)™ has much cheaper running cost than salt water softeners. One hospital spends £30,000 a year on salt.

No labour costs tried up with filling softeners up with salt.

Advanced Crystallisation Process (ACP)™ does still give you many of the same benefits of salt based units.

Kind to the environment

When water softeners regenerate they are consuming many thousands of liters water and many tons of salt a year.

The salt goes into sewage systems which can cause some problems when discharged into rivers. In some parts of California they have been banned because of these problems.

Limescale also is very bad for the environment as it increases energy usage as well increasing equipment failure.

Advanced Crystallisation Process (ACP)™ doesn’t consume any salt or water and therefore has never been banned. It also stops limescale build up so you still get the environmental benefits without the problems.

The Advanced Crystallisation Process (ACP)™ Range

Advanced Crystallisation Process (ACP)™ Mini S

The Advanced Crystallisation Process (ACP)™ Mini S is used to supply a single shower unit.

Advanced Crystallisation Process (ACP)™ S15

The Advanced Crystallisation Process (ACP)™ S15 is used to supply small domestic boiler units.

Advanced Crystallisation Process (ACP)™ S20

The Advanced Crystallisation Process (ACP)™ S20 is used to supply an entire domestic home or small business premises.

Advanced Crystallisation Process (ACP)™ H20

The Advanced Crystallisation Process (ACP)™ H20 is used to supply a large commercial property (ie. a hotel or residential home).

Would you like to know more about Advanced Crystallisation Process (ACP)™ ?

Simply fill in the form below, send us any questions, and we'll get back in touch with you.

Sign up to our newsletter

We will get back to you as soon as possible

Please try again later

Legionella Consultancy Services Ltd (LCS) is a well-established and innovative company that provides services to assess and manage the risks of legionella. We work with you to ensure your buildings and facilities are compliant with Government regulations and support you to establish sound and timely procedures. We are conscious of financial costs and always advocated cost-effective options.

Legionella Consultancy Services Ltd © 2023 • All rights reserved